Friction drive bicycle engine kits are the easiest engine kits to run and install. Unlike standard “dry clutch” bike engines that mount in the center of your bike and into the wheel, "friction drive" engines simply mount over your rear tire and start as soon as you pull the pull-start rope. People choose friction drive motors for many different reasons. They're leaps and bounds easier to install than 2-stroke center-mount engines and 4-stroke engines that require you to change out your bike's cranks, perfect for people without a lot of time or knowledge. Friction-drive engine kits are also more compatible than other engines because you mount it over the wheel. You're not stuck using a 26" wheel beach cruiser- you can use a mountain bike, city bike, or even a road bike with this type of engine. The

Flying Horse 4-Stroke 38cc Lock-n-Load is Flying Horse’s first friction drive engine kit, and it couldn’t be easier to install. Here we’ll show you how to install Flying Horse’s friction drive motor, but this is a pretty universal guide to mounting a friction drive motor if you have a Grubee or Stinger friction drive engines. To install these engines all you need are these tools:

- Adjustable Wrenches (or a 14mm socket wrench)

- Zip ties

- A box cutter (or a sharp knife)

- A wire stripper

- Electrical tape

- Compact drill with 1mm and 5mm drill bits

Here’s what comes with the Lock-n-Load engine (other engines may come with different mounts):

First, you’re going to install the square-shaped mount that goes on your bike's seat stay. Place the flat plate underneath the seat stay, the square piece above the seat stay, and hand screw the three bolts and screws into place. BE SURE THE MOUNT IS CENTERED, and that your bolts are torqued evenly with a socket wrench or adjustable wrenches:

Next, it’s time to install the engine to the main mount. Put the bevel side of the cylinder connector on the engine and then the mount on top of that (the brass cup should fit inside of the connector). Hand tighten the 4x black bolts with washers, then torque them down with a wrench in an “X” pattern:

Now we’re going to mount the support brackets on to your bike. Because bikes vary in size you’ll want to make sure you adjust the brackets to allow clearance of the engine mount. Take the nuts off the wheel, install the brackets on each side of the wheel, adjust, and fasten the wheel nuts. Make sure the slots on the wheel brackets go from bottom left to top right diagonally (you won’t be able to throttle properly if they’re the wrong way):

Then mount the engine to the mounting hardware (you might want an extra set of hands for this part, but it’s not necessary). Take the bolt out of the square mounting bracket, align the front of the mounting plate with the ports on the bracket, and send the bolt through the bracket and plate:

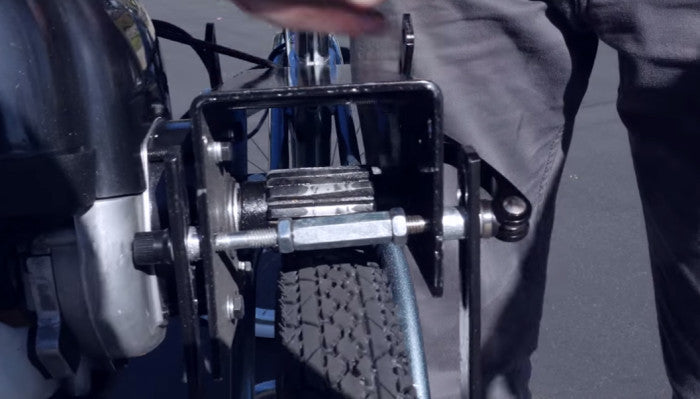

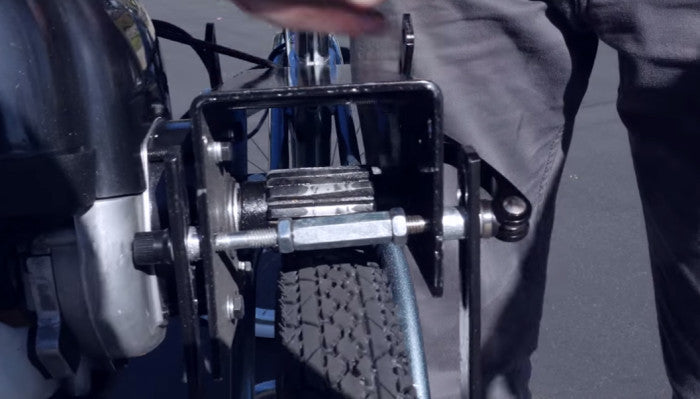

Move to the back of that mounting plate and install the quick-release. Put one bolt into the engine side of the plate and fasten it with a spacer and nut. Install the long, metal nut on to that screw. After that, do the same with the other end of the bolt (with the quick-release lever) by sending the bolt through the wheel brackets. Then attach the bolts:

Now you install the throttle cable and kill switch. Send the beaded end of the cable through the cable port on the carburetor, then into the throttle rocker. Run the throttle cable along the frame and zip-tie the cable-

BUT DO NOT TIGHTEN THEM ALL THE WAY YET. Take the kill switch and send it along the same path as the throttle cable, with the cable ends toward the engine. Wire the kill switch to the motor (black wire to black wire, red wire to red wire). Once that’s complete tighten the zip ties:

Next, you’re going to install the throttle handle. Start by taking off the existing grips (you may need to use a razor to slice the grips to pull them off). Once they're off, take the compact drill and drill a 1mm pilot hole at about 4.25 inches from the end of the bar. Drill into that hole with a 5mm drill bit for the kill switch mounting pin:

After that, install your throttle handle into the kill switch, and install the kill switch on to the handlebar by lining the kill switch notch into the drilled hole. Bolt the top half of the kill switch around the throttle handle and fasten the screws:

(Note: If you have a gas tank that’s pre-installed on to your motor you’re ready to ride! If you have an external gas tank, just install it as you would with any other engine kit: gas tank on top of your top bar of the frame and brackets below it to secure it to the frame.)

Once you’re done it’s all about tuning. Take out as much slack as you need from the throttle cable by adjusting the tension on the handle and cable port on the engine. If need be, you can also adjust the idle by tightening or loosening your carburetor’s idle screw.

When breaking your motor in we recommend using Maxima 4-stroke Break-In Oil for about 100 miles. While you’re breaking it in, make sure to take it easy and vary the RPM’s to ensure a long engine life. After break-in, we recommend using Maxima Pro Plus 10w30 4-stroke Scooter Motor Oil. Pull the pull start rope and engage the motor to the wheel. It might take multiple times to start, but once it does lower the motor down on to your wheel. To do that, simply unlock the quick-release, move the mounting plate down so that the roller grips the tire (not too hard, but not too soft either), then tighten the quick-release. It may take you a few times to find the sweet spot for that fit, but once you do you’ll know it:

If you're more of a visual learner, take a look at our

Friction Drive bike engine installation video for a step-by-step walk-through of putting one of these motors on your bike. Who knows? You might just ditch that 2-stroke and upgrade to a less stressful form of transportation...

20 comments

BikeBerry

“Hello,

To place an order you can place it directly online at <a href=""https://www.BikeBerry/"" rel=""noopener noreferrer"" target=""_blank"">BikeBerry or by giving us at call at 1-800-317-0479 Monday-Thursday 8:30 AM – 5:00 PM PST. and on Fridays 8:30 AM – 4:00 PM PST."

Anonymous

How do I order?

BikeBerry

“Hello Michael.

We actually do! This is our newest addition to our 4 Stroke Engine Kits. Check out the BBR Tuning 38cc 4-Stroke Rear Axle Drive Engine Kit <a href=""https://www.BikeBerry/gas-engine-kits/4-stroke-bike-engine/bbr-tuning-38cc-4-stroke-rear-axle-engine-kit.html"" target=""_blank"" rel=""noopener noreferrer nofollow"">here. We hope you enjoy it as much as we do."

BikeBerry

“Hello Michael.

We actually do! This is our newest addition to our 4 Stroke Engine Kits. Check out the BBR Tuning 38cc 4-Stroke Rear Axle Drive Engine Kit <a href=""https://www.BikeBerry/gas-engine-kits/4-stroke-bike-engine/bbr-tuning-38cc-4-stroke-rear-axle-engine-kit.html"" target=""_blank"" rel=""noopener noreferrer nofollow"">here. We hope you enjoy it as much as we do."

Anonymous

Aloha I already have a Roadbug friction drive kit, with a Honda 4 stroke but i am looking into your kits and this information is rad.

Anonymous

“Do you have a 4 stroke kit which is mounted above the pedals and drives the pedal sprocket? I want to be able to use the gears on the rear wheel.

Thank you,

Mike”

BikeBerry

“Hey Ron.

Our<a href=""https://www.BikeBerry/gas-engine-kits/2-stroke-bike-engine.html"" target=""_blank"" rel=""noopener noreferrer nofollow""> 2 Stroke Engine Kists can go anywhere between 25-40mph depending on the gear ratio and the weight of the rider. Our <a href=""https://www.BikeBerry/gas-engine-kits/4-stroke-bike-engine.html"" target=""_blank"" rel=""noopener noreferrer nofollow"">4 Stroke Engine Kits can go about 25-35mph thorough any steep hills and higher altidutes."

BikeBerry

“Hi Steve!

Unfortunately, that would not be possible due to the size of the frame and the 7 speed cassette. We would always advise using any male 26"" bicycle such as a beach cruiser or mountain bike for the best results."

Jw

Yes it’s a twist grip throttle just like a motorcycle.

Jw

Yes it’s a twist grip throttle just like a motorcycle.

Anonymous

how fast does it go?

Anonymous

I want to mount on a ladies 7 speed twist gear bike with hand brakes. Is that possible?

Anonymous

I have a Giant Cypress mountain bike and it worked just fine for me folks.

Lakhbir

Okay so i had a question about the throttle. How would one decrease or increase in speed? is it a lever type action? or like a normal motorcycle where i just turn the grip.

BikeBerry

Hey there, Pedro! You can definitely mount a friction drive engine to a fat tire bike. As long as the width of your tire is 3.5" or smaller, you’ll be fine. Anything bigger than that and you might need to modify the friction drive mount.

pedro

Can I put a four stroke friction driver motor on a fat bike

BikeBerry

If it’s 16" and you have a top bar to mount a tank you may actually be able to set a 2-stroke in that frame. I’ve seen that model bike before, and it seems like you may not need to do much modification if you want to go with a male frame. However, if you have a female frame you might be better going with a friction drive motor. Otherwise to fit a 2-stroke on to a female frame you have to make some modifications to mount the engine and the tank.

mike

I have a fungi 29" montery 3.0 its an older model I believed the down tube is 16" so the triangular pattern is small I don’t know if an engine 2or4 stroke would fit in their & have quick realease hard tail

BikeBerry

Awesome! I’m not too familiar with that bike, but with any mountain bike make sure it’s a hardtail frame with round tubes. Also check out this video we made for a more detailed explanation: https://www.youtube.com/watch?v=NR8-IcrbwaI

Chris

I was wondering if the 66/80cc motor would fit on my trek 820 mt bike